It depends on many elements when LED applies in the configuration form, including the requirement of the application, LED index and quantity, input voltage, efficiency, heat dissipation associated, size and layout constraints, optics, etc. The most simple configuration is a single LED design applied on many occasions like car interior overhead light, map light, reading light, etc. Due to the LED chip having a small power, and low working voltage, so it needs to adopt most series and the parallel way to meet the requirement in process of making the LED lighting fixtures. We should be serious with connection bread as well, cause LED is special with nonlinearity, while there will have a big change of bread current if the voltage has a little change, then it will have a bad effect on the LED lifespan to a large extent deal with it improperly.

In the following, there are introduction about some connection ways of LED bread.

Integral Series Form

Simple Concatenation

In general, the simple concatenation is LED1 link LEDn from start to the end. When the LED breads start working, the current flowing of each bread is equal, almost all of them are the same lighting intensity from a batch of same specific lamp beads. Therefore, the simple concatenation has the characteristics of simple circuit and convenient connection.

2 Series Form With Parallel Zener Diode

Each LED is connected in parallel with an improved series connection form of Zener diode. In this connection, the breakdown voltage of each Zener diode is higher than the operating voltage of the LED lamp bead

In the normal operation of the LED beads, due to the Zener diode VD1 link to VDn does not conduct, and the current mainly flows through LED1 ~ LEDn, so when the LED beads in the string of damaged LEDs caused by the string open circuit, in addition to the faulty LED beads, the other LEDs still have current through and light. This connection has a high reliability compared to the simple series connection shown above.

Advantage and Disadvantage of Simple Concatenation

Advantage

The breads in series is a most reasonable way of connection. essential feature of all LED bread current is equal of series circuit, so that the power difference between each bead is equal to their voltage difference, not higher than his. It really inclusive for inconsistency of LED lamp beads. By the side

Disadvantage

The lamp bead open will cause the whole lamp does not towork, though the short circuit condition has no effect on the whole lamp.

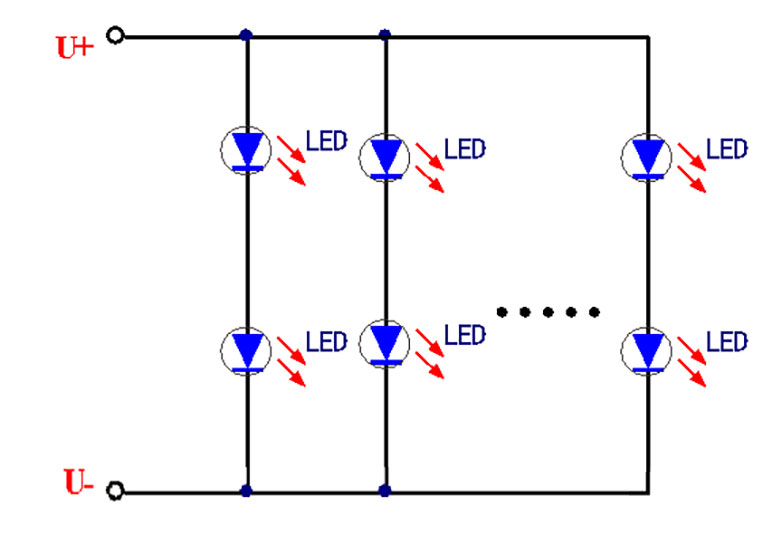

Parallel Form

In general, the parallel form is LED1 link LEDn from start to the end. When the LED breads start working, the voltage flowing of each bread is equal

Because of the special characteristics of LED beads, they are current-based devices, and every time there is a small change in voltage on the LED bead, it will cause a large change in current. In addition, LED manufacturing technology is currently limited, even if the same batch of LED beads, its performance differences are inherent, so when LED1 ~ LEDn work, the current of each LED bead is not equal.

It follows that the uneven distribution of current to each LED bead may cause the life of an over-current LED to be drastically reduced or even burnt out. This connection method is relatively simple. However, the reliability is not high, especially for applications with a high number of LEDs, which can cause failures.

Independently matched parallel form

Individually matched parallel forms are a good way of doing this. Each LED in this way has a current alone adjustable (driver V + output L1 ~ Ln respectively.) Ensure that the current flowing through each LED in its required range, with good driving effect, single LED protection complete, failure does not affect the work of other LEDs, can match the LEDs with large differences and other characteristics.

The main problem is that the entire driver circuit is complex, the cost of the device is high and the volume occupied is too large for a large number of LED circuits.

The hybrid form is a combination of the respective advantages of series form and parallel form, the main form has the following two

A hybrid form of combining first and then stringing

The first parallel and then the series reflects the advantages of the series, but can not avoid the shortcomings of the parallel, so it is not the best option for connection though this mode is most used in fluorescent lamps. For example, 18w fluorescent lamps are basically 4 and 24 series.

There are two main reasons for this phenomenon: First, if four 24-series lamp beads are connected in parallel, a lot of wires must be added to the long and narrow aluminum substrate, otherwise, which will easily cause an open circuit or a short circuit. The second is to purchase lamp beads in large quantities, which can make the classification more detailed and ensure consistency.

A hybrid form of concatenation

It is a more reasonable LED connection method, which absorbs the advantages of the two methods first.

For some small home workshops, it is difficult to ensure the consistency of lamp beads, so using this mode as much as possible can maximize the service life of lamps.